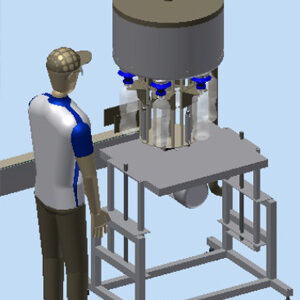

The bottles enter the machine on a conveyor; a pneumatic gate system allows the containers to stand under the filling heads and keeps the rest of the containers isolated on the conveyor line. The filling operation then starts to the pre-set count. Each filling nozzle is fitted with its own positive shut off valve, which shuts off the product flow once filling is completed and prevents excess dripping. The machine is fitted with a short stroke diving system.

A product hopper tank is supplied with the machine, which is pneumatically controlled by means of modulating valve or probe or mercury switch.

- PLC Controlled

- Fully automatic

- Full diving system to reduce foam in certain products is optional

- Positive shut off valves

- Neck Gripper / Drip Tray is optional

- Filling speed depends on size of container / bottles and viscosity of liquid / product