A product hopper tank is supplied with the machine and is pneumatically controlled by means of either a modulating valve or probe or level switch.

- PLC Controlled

- Fully automatic

- Full diving system to reduce foam in certain products is optional

- Positive shut off valves

- Filling speed depends on size of container / bottles and viscosity of liquid/product

Retractable Drip Tray:

This unit consists of a stainless steel trough, which slides in and out underneath the nozzles after each cycle. Any product that may drip off the nozzle will be caught in the drip tray and will be drained away to a designated point.

Two (2) Head Gear/ Peristaltic Pump Filler – Semi Diving Nozzle:

Two (2) Head Gear/ Peristaltic Pump Filler – Full Diving Nozzle:

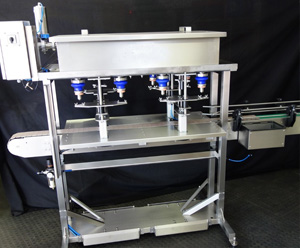

Four (4) Head Gear/ Peristaltic Pump Filler: