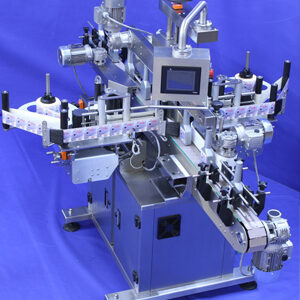

Stepper motors and drives are being used together with a Human Machine Interface to ensure ease of setup and highly accurate labelling.

Electronic Setup for up to ten containers are stored on the system making changeovers easier between different containers.

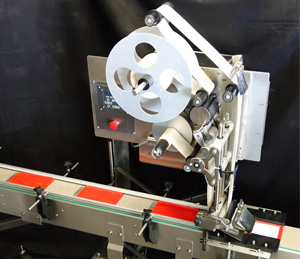

As a standard the machine is supplied to accommodate a 145mm high web width labels but additional extended rollers can be supplied to accommodate labels with a web width of up to 260mm.

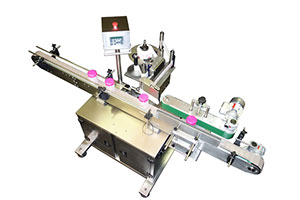

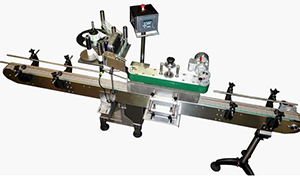

A 2.5m conveyor with an 82.5mm ACETAL belt will transport the container though the system to apply the labels. A double sided in-feed centralizing unit or double sided scroll system orientates the container prior to an overhead stabiliser grabbing hold of the container in its orientated state and supporting the container though the area where the labels are being applied. Flat panel labelling accessories ensure good adhesion of the label onto the bottle. All drive motors have YASKAWA variable speed facility as a standard.

| Scope | |

| Bottle Sizes | Various |

| Cap Sizes | NA |

| Bottle Shapes | Oval |

| Required Production Rate | 60 Bottles per minute |

| Labels | |

| Max Label Web Width | 145mm / 22mm / 260mm |

| Min Label Length | 8mm |

| Label Reel Core Diameter | 76mm |

| Label Material | Most self-adhesive labels available |

| Machine | |

| Conveyor | Variable speed slat chain |

| Conveyor Length | 2.5m (Can be extended) |

| Linear Speed | 4-40m/min |

| Overall Dimensions (LxWxH) | 2500 x 1450 x 1500 |

| Weight (Approx) | 250kg |

| Controls | |

| Stopper Drive | KINCO |

| Label Gap Sensor | Optical / Micro Switch |

| Product Sensor | Coaxial Polarised Retroreflective |

| Control Panel | 64MHz Micro Processor |

| Utilities | |

| Compressed Air | 600kPa if Hot Foil is fitted |

| Electrical Supply | 220VAC 50Hz single phase |

| Electrical Consumption | 2kW |